Surface Cleaning Spray Washing Lines

Spray Surface Treatment Lines

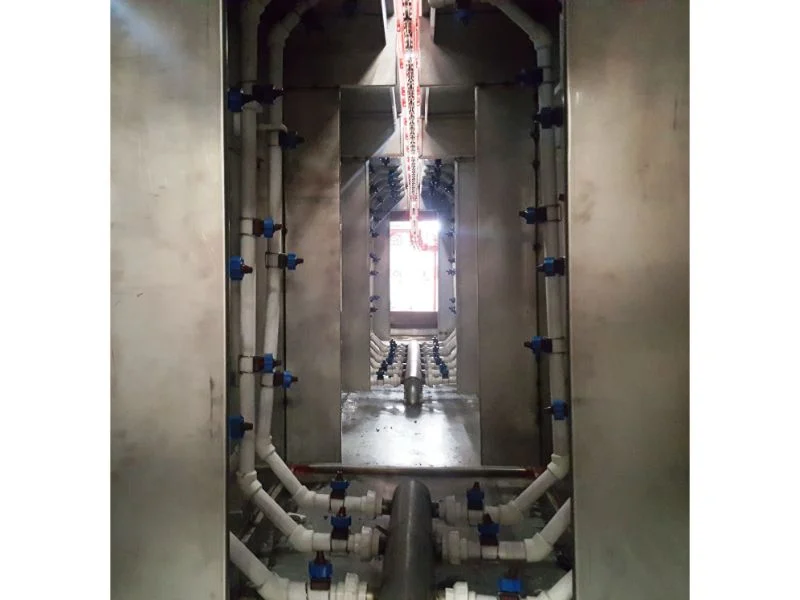

In cases where high production capacity is in question, systems with spray lines are more economical. In these systems, moving parts suspended on the conveyor enter into a chemical reaction at the appropriate time, pressure, flow and temperature while passing through the active sections in the spray tunnel. The length of the spray tunnel is determined by the process and conveyor speed to be used.

Technical Specifications

Bath tanks and tunnel are manufactured from Cr-Ni, epoxy painted Black steel sheet or PP material, depending on the process to be used. Tank walls are insulated with glass wool against heat loss, and tunnel walls are insulated with styrofoam and covered with electrostatic powder painted 1.2mm sheet metal. In the heating of hot bath tanks, gas and liquid fuel burners are used together with a hot water boiler and plate heat exchanger system or a thermoblock heating system, depending on the process. There are steam evacuation fans in the appropriate sections of the tunnel. The system is controlled via the main plant control panel.